How to judge the progressiveness of reflow equipment technology? The practical case of Jinuos Electronics tells you

Zeit:2024-08-15 14:45:57Herausgeber:Jeenoce

In the wave of intelligent manufacturing, reflow soldering is a key link in the SMT (Surface Mount Technology) production line, and its progressiveness technology is directly related to product quality and production efficiency.

Faced with the dazzling array of reflow soldering equipment manufacturers in the market, many companies cannot help but ask:

Which reflow soldering equipment manufacturer is truly leading in technology

In the wave of intelligent manufacturing, SMT (Surface Mount Technology) technology has become an indispensable production process in fields such as consumer electronics, automotive electronics, medical devices, and new energy due to its high density, high precision, and high reliability.

As a leader in the field of intelligent manufacturing, Suzhou Jeenoce Electronics Co., Ltd. deeply understands that reflow soldering technology, as a crucial part of SMT production lines, directly determines the final precision and reliability of products.

From precise soldering of mobile phone chips to complex automotive electronic control modules, to medical devices related to human health and leading new energy equipment for the future, Jeenoce Electronics, with its profound accumulation and innovative advantages in reflow soldering technology, ensures that every link reaches the top level of the industry and safeguards customers' intelligent manufacturing journey.

Technical Analysis in Depth: Highlights of Reflow Soldering Technology at Jeenoce Electronics

Since its establishment, Suzhou Jeenoce Electronics Co., Ltd. has been deeply involved in the field of intelligent manufacturing and has rapidly risen to become a leader in the industry.

The company takes technological innovation as its core driving force, constantly breaking through traditional technological barriers, and is committed to providing customers with high-performance and high reliability intelligent manufacturing solutions.

Jeenoce Electronics has a research and development team composed of senior industry experts and young innovative forces. They keep up with the pace of the times, keenly observe market trends, and transform the most cutting-edge technological achievements into actual productivity.

In the field of reflow soldering technology, Jeenoce Electronics not only inherits the exquisite craftsmanship and advanced technology of international leading brands such as REHM in Germany, but also conducts a large amount of independent research and innovation on this basis, forming a unique technical system.

The company always regards "quality first, customer first" as its business philosophy, strictly controls every production process, and ensures that every reflow soldering equipment can meet the highest industry standards.

At the same time, Jeenoce Electronics actively builds a comprehensive after-sales service system, providing customers with all-round and 24/7 technical support and guarantee, winning widespread market praise and customer trust.

It is precisely with such technological innovation strength and high-quality service level that Suzhou Jeenoce Electronics Co., Ltd. has established a good brand image in the field of intelligent manufacturing and become a trusted partner for many enterprises.

In the future, Jeenoce Electronics will continue to adhere to the development philosophy of "innovation led, quality-oriented", continuously promote the progress and upgrading of intelligent manufacturing technology, and contribute more to the development of the industry.

Explanation of core advantages:

German quality, source guarantee: the excellence of REHM reflow soldering

On the journey of exploring intelligent manufacturing, Suzhou Jeenoce Electronics Co., Ltd. has partnered with Germany's REHM to bring unprecedented high-quality reflow soldering solutions to the industry.

REHM, as a technology giant originating from Germany, has become synonymous with outstanding performance due to its exquisite craftsmanship and advanced technology in reflow soldering equipment.

The following points will elaborate on the excellence of REHM reflow soldering:

German craftsmanship and ingenuity: The REHM reflow soldering equipment inherits the rigor and precision of German manufacturing, with each process carefully designed and strictly controlled. From material selection to processing, from assembly to debugging, all reflect the ultimate pursuit of quality by German craftsmen. This spirit of craftsmanship ensures that the REHM reflow soldering equipment reaches the industry's top level in durability, stability, and accuracy.

Advanced technology, leading the trend: REHM always stands at the forefront of technological innovation, constantly applying the latest technological achievements to the field of reflow soldering. Its unique temperature control system, efficient heat conduction design, and intelligent operation interface not only improve production efficiency, but also ensure the stability and reliability of welding quality. The application of these advanced technologies has set a technological benchmark for REHM reflow soldering equipment in the industry.

Excellent performance, trustworthy: Thanks to Germany's exquisite craftsmanship and advanced technology, the REHM reflow soldering equipment performs excellently in terms of performance. Whether it is handling fine soldering of complex circuit boards or meeting the efficient requirements of large-scale production, REHM is able to complete tasks with ease. Its outstanding performance has won the trust and praise of many customers worldwide.

Technological Innovation, Leading the Future: Jeenoce and REHM Jointly Draw a New Chapter in Reflow Soldering Technology

In the rapidly changing field of intelligent manufacturing, Suzhou Jeenoce Electronics Co., Ltd. has partnered with Germany's REHM to continuously make technological innovation the core driving force for industry development.

The two have closely cooperated, deeply integrated market demand and advanced technology, and continuously and deeply innovated reflow soldering technology, jointly leading the future development trend of the industry.

The following points provide a detailed explanation of the specific measures and achievements of Genomics and REHM in technological innovation:

Intelligent temperature control system: precise control, quality upgrade

Jeenoce assisted REHM in jointly developing a new generation of intelligent temperature control system, which can monitor and accurately adjust the temperature inside the furnace in real time, ensuring that temperature fluctuations during the welding process are controlled within a very small range. This innovation not only effectively avoids welding defects caused by uneven temperature, but also significantly improves the welding quality and reliability of the product. At the same time, the intelligent temperature control system can automatically adjust the temperature curve according to different welding materials and process requirements, achieving personalized customization and meeting the diverse needs of customers.

Efficient heat conduction design: Speed up and reduce consumption, green production

In order to further improve production efficiency and reduce energy consumption, Jeenoce has collaborated with REHM to optimize the heat conduction design of reflow soldering equipment. By using advanced heat conduction materials and structural optimization techniques, the equipment can transfer heat more quickly and evenly, thereby shortening the welding cycle and improving production efficiency. At the same time, efficient heat conduction design also reduces energy waste and emissions, in line with the concept of green production, and helps enterprises achieve sustainable development.

Intelligent operation interface: convenient and efficient, new experience of human-computer interaction

Jeenoce and REHM are well aware of the importance of intelligence in modern production, and therefore pay special attention to the intelligent upgrade of reflow soldering equipment. The two have jointly created a brand new intelligent operation interface, which is designed to be concise and clear, with intuitive and easy to understand operation processes. Users can easily complete device settings, parameter adjustments, fault diagnosis, and other operations through the touch screen, greatly improving production efficiency and operational convenience. In addition, the intelligent operation interface also supports remote monitoring and data analysis functions, providing enterprises with more comprehensive production management and decision support.

Customized solution: flexible response to meet personalized needs

In today's increasingly diversified market demand, Jeenoce and REHM are committed to providing customized reflow soldering solutions for customers. By gaining a deep understanding of customers' production processes and product characteristics, both can provide customers with comprehensive services from equipment selection, process design to installation and commissioning. Customized solutions not only meet the personalized needs of customers, but also ensure the optimal performance and matching of equipment, creating greater value for customers.

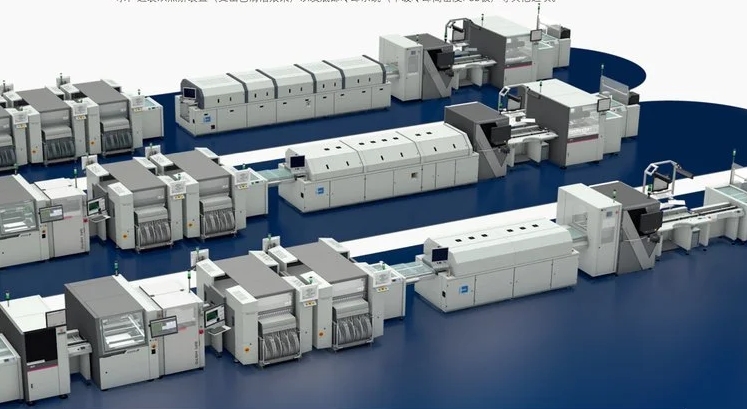

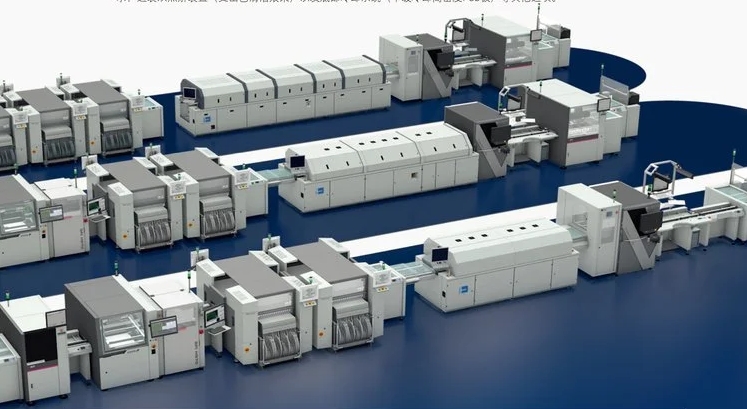

Integration of the entire production line, seamless integration: Jeenoce and REHM join hands to create an efficient production chain

On the broad stage of intelligent manufacturing, Suzhou Jeenoce Electronics Co., Ltd. and Germany's REHM not only focus on the excellent performance of reflow soldering technology, but also are committed to providing customers with comprehensive solutions from SMT production to whole line Inline transformation.

This integrated service model ensures the smooth and efficient production chain, bringing unprecedented competitive advantages to enterprises.

Here are several key points of this service model:

One stop equipment supply: high-quality reflow soldering as the core

Jeenoce and REHM have formed a strong alliance to provide customers with world-class reflow soldering equipment. These devices, with their exquisite craftsmanship, advanced technology, and outstanding performance, have become the core force of SMT production lines. From high-precision small devices to large-scale systems that meet the needs of large-scale production, Jeenoce can accurately match according to the specific needs of customers, ensuring that each device can perform at its best efficiency.

Whole line planning and design: customized solutions

Realizing that optimizing a single device is not sufficient to meet the modern production's demands for efficiency and flexibility, Jeenoce has further expanded its service scope and provided customized solutions for whole line planning and design. The team has a deep understanding of the customer's production process, product characteristics, and production capacity requirements, and combines REHM's advanced technology to tailor a full line production plan for the customer. From equipment layout, process flow to logistics system, every link has been carefully planned to achieve the optimal configuration of the production chain.

Inline transformation and upgrade: seamless integration, improving efficiency

With the continuous advancement of technology and changes in the market, enterprises often need to transform or upgrade their production lines to meet new production needs. Jinuos and REHM, with their rich experience and professional technical strength, are able to provide customers with efficient Inline transformation services. Whether it's adding new equipment, replacing old equipment, or optimizing the layout of existing production lines, Jeenoce can ensure seamless integration during the renovation process, minimizing downtime and production losses to the greatest extent possible. The renovated production line will be more efficient, flexible, and intelligent, helping enterprises enhance their competitiveness.

Full process technical support and service: ensuring smooth production

In addition to providing high-quality equipment and solutions, Jeenoce also focuses on providing customers with comprehensive technical support and services. From equipment installation and debugging, operation training to daily maintenance and troubleshooting, Jeenoce can provide customers with timely and professional technical support. At the same time, the company has established a comprehensive after-sales service system to ensure that customers can quickly respond and solve any problems encountered during use. This comprehensive service model provides customers with a solid backing to ensure the smooth and efficient operation of the production chain.

Industry Application Example: Successful Application Cases of Jeenoce Electronics in Multiple Fields

Suzhou Jeenoce Electronics Co., Ltd. has achieved significant application results in multiple fields such as consumer electronics, automotive, medical, and new energy with its advanced technology and solutions.

The following are specific cases of the progressiveness of Innos electronic technology through close cooperation with Foxconn, Harman, BYD and other companies:

1. Consumer electronics field

Partner: Foxconn

Case Overview: Jeenoce Electronics provided multiple intelligent manufacturing solutions, including reflow soldering, for Foxconn's consumer electronics production line. Through customized whole line integration services, Jinuos has helped Foxconn achieve intelligent upgrades to its production lines.

Data comparison:

Production efficiency improvement: Compared to before the upgrade, production efficiency has increased by about 30%, significantly shortening the time to market for products.

Reduction in defect rate: Through precise temperature control and optimized process flow, the defect rate has been reduced by 20%, improving product quality and customer satisfaction.

2. Automotive field

Partner: BYD

Case Overview: Jeenoce Electronics and BYD have entered into a deep cooperation in the manufacturing of automotive electronic systems, particularly in the joint development of automotive grade interactive host system platforms, where significant breakthroughs have been made. The reflow soldering equipment and technical support provided by Jeenoce provide a solid guarantee for BYD's production of automotive electronic components.

Data comparison (estimated data, specific data not disclosed due to internal requirements):

Shortened production cycle: By optimizing the production process and adopting efficient heat conduction design, the production cycle has been shortened by about 25%, improving production flexibility.

Improvement in welding quality: The application of intelligent temperature control system has increased the stability of welding quality by 15%, reducing rework and scrap caused by welding problems.

3. Medical field (confidentiality agreement)

Case Overview:

Jeenoce Electronics has successfully applied its high-precision and high reliability intelligent manufacturing solutions to the production line of medical equipment. For example, in the precision welding and assembly process of medical devices, the reflow soldering equipment and technical support provided by Innolux ensure the manufacturing accuracy and safety of medical devices.

Estimated data:

Improved welding accuracy: Compared to traditional welding methods, the welding accuracy has been improved by 10 microns, meeting the demand for high-precision manufacturing of medical devices.

Improvement in yield rate: Through strict process control and quality control system, the yield rate has increased by about 15%, reducing production costs and medical risks.

Jeenoce Electronics has achieved significant application results in multiple fields with its advanced technology and solutions.

Through close cooperation with Foxconn, Harman, BYD and other companies, Innos not only demonstrated its progressiveness technology, but also brought tangible economic and social benefits to customers.

In the future, Jeenoce Electronics will continue to deepen its cultivation in the field of intelligent manufacturing, providing efficient, intelligent, and flexible solutions for more industries.

Customer voice: Trusted choice, learn from excellence together

On the path of pursuing excellence and innovation, Suzhou Jeenoce Electronics Co., Ltd. always regards customer satisfaction and trust as the most valuable asset.

The following are real feedback and evaluations from customers in different fields, which not only recognize the excellent performance of Jinuosi Electronics in service quality, technical support, and after-sales guarantee, but also provide us with a strong driving force for continuous progress.

Foxconn representative:

The cooperation with Jeenoce Electronics has deeply impressed us with the essence of 'professionalism' and 'efficiency'. From the initial requirement communication of the project to the implementation and landing in the later stage, the Jeenoce team has always maintained a high degree of professionalism and responsibility. Their reflow soldering equipment has excellent performance, significantly improving our production efficiency. Moreover, throughout the entire cooperation process, the technical support team responded quickly and solved every technical problem we encountered. It is worth mentioning that Jinuosi's after-sales service is very good, allowing us to have no worries during use. We trust such a partner very much

Harman Project Leader:

In the precision manufacturing of automotive electronic systems, we are extremely strict in selecting our partners. Jeenoce Electronics stands out among many competitors with its advanced technology and solutions. Their service team not only has strong professional capabilities, but also has an excellent service attitude, always able to think from our perspective and provide the most suitable solutions. Especially in terms of technical support, Jeenoce' technical expert team can always respond quickly to our needs to ensure the smooth operation of the production line. In addition, their comprehensive after-sales service system allows us to feel unprecedented peace of mind and convenience during use. Cooperation with Jeenoce Electronics is an important guarantee for the success of our Harman project

BYD engineer:

In the context of the rapid development of new energy vehicles, our requirements for production equipment are also increasing. The reflow soldering equipment and technical support provided by Innolux Electronics perfectly meet our needs for efficiency, precision, and reliability. During the project implementation process, Innolux's service team demonstrated extremely high professionalism and dedication. They not only helped us optimize the production process, but also improved product quality. More importantly, their after-sales service is very thoughtful, whether it is equipment maintenance or technical upgrades, they can respond in a timely manner and handle them properly. Our cooperation with Innolux Electronics has strengthened our confidence in continuous innovation in the field of new energy vehicles

The customer's voice is the most authentic feedback and the highest praise for our work.

Suzhou Jeenoce Electronics Co., Ltd. will continue to adhere to the service concept of "customer-centric", continuously improve service quality, strengthen technical support, and improve after-sales support, striving to become a trusted partner for every customer.

International North Exchange Session

What factors do you value the most when choosing reflow soldering equipment? For example, performance stability, production efficiency, cost-effectiveness, or technological innovation?

What are the similarities and differences in the demand for reflow soldering equipment in different industries? How to customize equipment selection plans based on industry characteristics?

We sincerely invite every reader to leave your valuable insights or questions in the comment section.

Whether it is the difficulties you encounter in practical work or your unique insights into industry trends, they will become valuable resources for us to learn together.

Let's work hand in hand to inspire new inspiration and creativity through communication and collision.

Additionally

——Expert Answer Preview: Authoritative Voice, Professional Guidance

In order to further enhance the value of interactive activities, we will regularly invite authoritative experts and technical teams in the industry to join our platform.

They not only possess profound professional knowledge, but also have rich practical experience.

They will provide professional and detailed answers to various questions raised by readers, helping them better grasp the pulse of the industry and solve practical problems.

You can leave your question directly in the comment section, or go to

Milling cutter online slitting machine - Curve slitting machine - Offline slitting machine - Jeenoce Electronics

Conclusion: Joining hands with JEENOCE to create a new chapter in intelligent manufacturing

During the journey of review and exploration, Jeenoce Electronics felt the outstanding achievements and unlimited potential of reflow soldering equipment in the field of SMT.

As a leader in this field, Jeenoce Electronics has won widespread recognition and praise in the market with its profound technological accumulation, innovative product design, and excellent customer service.

Summary emphasizes:

Jeenoce Electronics, as a leader in the field of reflow soldering equipment, has always been at the forefront of technology and constantly leads industry changes.

We have advanced manufacturing processes, precision testing equipment, and a comprehensive quality management system to ensure that every piece of equipment can reach the top level in the industry.

At the same time, the technical team of Innolux Electronics is constantly innovating and committed to transforming the latest technological achievements into practical applications, providing customers with more efficient, intelligent, and reliable solutions.

It is the dual guarantee of these technologies and services that has made Jeenoce Electronics a trusted partner for many enterprises, jointly promoting the rapid development of intelligent manufacturing.

As a partner, the value of Jeenoce Electronics goes far beyond providing high-quality equipment and services.

We are a trustworthy partner who is willing to work hand in hand with our customers to face market challenges and seize development opportunities together.

Whether it's technical consultation, solution design, or after-sales support, Jeenoce Electronics will spare no effort to ensure that every detail of customer needs can be perfectly achieved.

Looking ahead to the future:

With the comprehensive arrival of the intelligent manufacturing era, we firmly believe that reflow soldering technology will demonstrate its unique charm and value in more fields.

As a leader in the industry, Jeenoce Electronics will continue to adhere to the development philosophy of "innovation, excellence, and win-win", continuously increase research and development investment, deepen technological innovation, and provide customers with more advanced and intelligent solutions.

Here, we sincerely invite every friend who is interested in the field of intelligent manufacturing to follow and participate in the technological innovation journey of Innolux Electronics together.

Let's work hand in hand, constantly break through ourselves in exploration and practice, and jointly create a beautiful future of intelligent manufacturing.

If you are fortunate enough, let Jeenoce Electronics be your bridge, connecting intelligence and manufacturing, and creating a new chapter in intelligent manufacturing together!